In the realm of heavy machinery, KTSU rubber tracks are becoming increasingly vital. Industry reports from leading manufacturers indicate that the demand for durable and efficient tracks is soaring. In 2026, projection data suggests a growth rate of nearly 8% in global sales of rubber tracks. This paints a promising picture for KTSU rubber tracks, known for their resilience and reliability.

With businesses expanding in construction and agriculture, the need for high-performance machinery is essential. KTSU rubber tracks provide superior traction and stability, crucial for various terrains. They enhance the operational efficiency of machines, contributing to higher productivity levels. However, certain aspects warrant reflection. Users often overlook maintenance, which significantly impacts track longevity.

Moreover, challenges in sourcing high-quality materials sometimes arise. Companies must address these issues to ensure that KTSU rubber tracks meet evolving industry standards. Investing in these tracks means committing to quality, yet it also requires vigilance and proactive maintenance practices. As the industry progresses, embracing both innovation and reflection will be key to maximizing the benefits of KTSU rubber tracks.

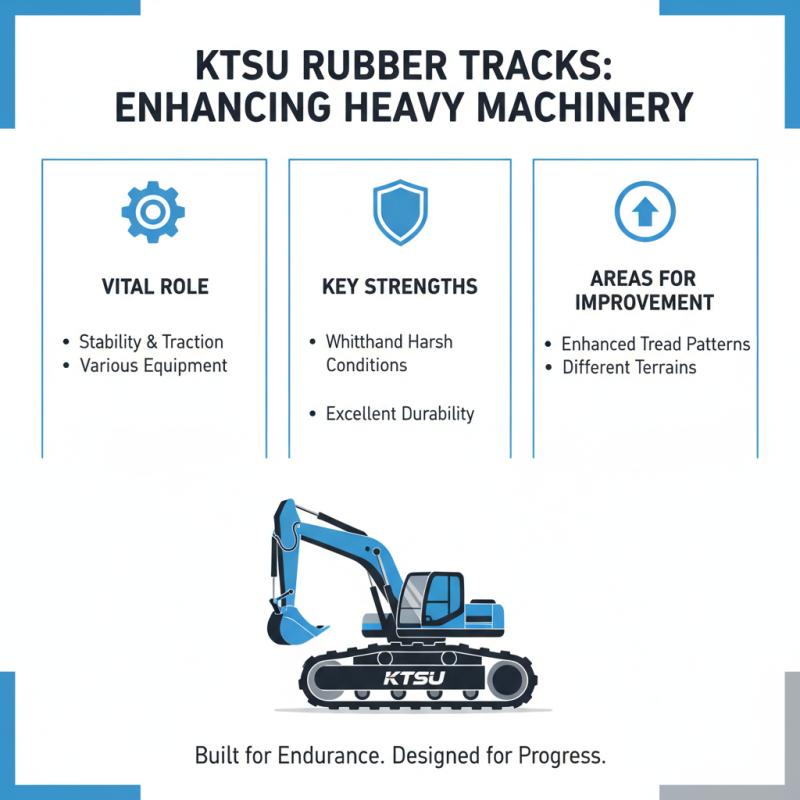

In the heavy machinery industry, KTSU rubber tracks play a vital role. They ensure stability and traction for various equipment. These tracks are designed to withstand harsh conditions. They offer excellent durability, yet there are areas for improvement. For instance, while many tracks perform well, some could benefit from enhanced tread patterns. Different terrains can challenge even the best tracks.

User feedback often highlights comfort as a critical factor. Operators want to navigate smooth and rough landscapes effortlessly. However, some users report issues with noise levels. This highlights a potential area for development. Manufacturers should focus on addressing these concerns to elevate user experience.

The future looks promising for KTSU rubber tracks. Continuous advancements are needed to enhance performance. Innovation in materials could further improve longevity. As the industry evolves, user input will guide enhancements. There is always room for improvement, and adaptation is crucial. The next few years may redefine expectations in the heavy machinery sector.

When considering rubber tracks for heavy machinery, performance is key. The design should enhance traction and stability. High-quality rubber tracks can handle various terrains. They should provide excellent durability against wear and tear. Many tracks feature reinforced steel belts, which strengthen the structure and extend their life.

Moreover, these tracks often come with unique tread patterns. The tread influences grip and movement. A suitable pattern can improve maneuverability on soft ground. If the tread is too shallow, it may lead to slipping. Operators need to assess their working conditions carefully.

Lastly, the weight and size of the rubber tracks matter greatly. Heavier tracks can increase stability but may slow down machinery. A balance between weight and performance should always be pursued. Attention to these specifications can prevent future setbacks in efficiency. Regular maintenance checks are crucial, even for high-performance tracks.

When it comes to heavy machinery, choosing the right rubber tracks is crucial. Different models serve various functions. Some are designed for traction on soft soil, while others excel in durability on rocky surfaces. Evaluating specific characteristics can guide your decision.

Durability is often a concern for operators. Many tracks show wear earlier than expected. This can lead to downtime and increased costs. Track patterns can impact performance too. A tread designed for maneuverability may sacrifice stability. Finding the right balance is essential for your needs.

Some brands emphasize performance while neglecting comfort. Operators need a smooth ride, especially for long hours. Vibration can affect productivity. Noise levels also matter; quiet machines often enhance the working experience. Therefore, reflect on the trade-offs when selecting your rubber tracks.

Maintenance of KTSU rubber tracks is crucial. Regular inspection can extend the lifespan significantly. According to industry reports, proper maintenance can increase track longevity by up to 30%. The first step is to keep the tracks clean. Accumulated dirt and debris can cause premature wear.

Check for signs of damage frequently. Look for cracks, cuts, and any signs of uneven wear. These issues can worsen if not addressed promptly. Report from the Heavy Equipment Manufacturers Association indicates that ignoring maintenance can lead to costly repairs.

Proper tension adjustment matters as well. Tension that is too loose or too tight can reduce the effectiveness of the tracks. Aim for specific tension levels recommended for your equipment type. Remember to store machines indoors when not in use. Exposure to extreme temperatures can degrade rubber materials. Regularly service the machinery to maintain optimal performance. As studies suggest, a proactive approach to maintenance leads to fewer failures and better productivity.

The development of KTSU rubber tracks has seen significant trends lately. As heavy machinery adapts to various terrains, the demand for high-quality rubber tracks increases. In 2022, the global rubber track market reached $5.5 billion. This number is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2030. Such statistics illustrate the increasing reliance on durable machinery.

Innovations in material technology have played a crucial role, enhancing grip and resistance. Some manufacturers are experimenting with more eco-friendly compositions, despite the challenges of achieving durability. For instance, recent tests indicated that natural rubber blends can reduce the overall carbon footprint by 20%. However, these materials often sacrifice lifespan and performance in rugged terrains.

The competition among manufacturers is heating up. Some focus on custom solutions while others prioritize mass production efficiency. Industry reports indicate that 45% of companies find it difficult to balance these approaches. There is room for improvement in aligning innovation with practical application. Companies must reflect on the need for adaptability in their offerings. This shift will ultimately satisfy diverse customer needs better.