Choosing the right rubber tracks for heavy machinery can significantly impact the performance, efficiency, and longevity of your equipment. As industry expert James Thornton, a renowned specialist in construction machinery, notes, "The right rubber tracks ensure optimal traction and provide the necessary support for safe and efficient operations." With a myriad of options available in the market, making an informed decision can be daunting.

When selecting rubber tracks, it's crucial to consider factors such as the type of machinery, the conditions in which it will be used, and the specific job requirements. For instance, working on soft or uneven ground may require tracks designed for improved traction and stability, while harder surfaces might necessitate more durable construction. By understanding the various specifications and features of rubber tracks, operators can tailor their choices to maximize productivity and minimize downtime.

In this guide, we will explore the essential aspects of choosing the best rubber tracks for your heavy machinery needs, highlighting the benefits of selecting the right track and the potential pitfalls of making an uninformed choice. With the right knowledge and expert insights, you can equip your machinery with tracks that best suit your operational demands, ensuring a seamless and effective performance.

When selecting rubber tracks for heavy machinery, several critical factors should be taken into account to ensure optimal performance and longevity. First, consider the type of terrain where the machinery will operate. For instance, rough, uneven grounds may require tracks with deeper tread patterns for enhanced traction, while smoother surfaces could benefit from tracks designed for reduced ground disturbance. Additionally, the weight of the machinery plays a pivotal role; heavier machines necessitate thicker, more robust tracks to withstand wear and tear while maintaining stability.

Another important aspect to evaluate is the dimensions and compatibility of the tracks with your equipment. Accurate measurements, including width and length, are essential to ensure proper fit and functionality. Incompatibility can lead to premature wear or even damage to the machinery. Moreover, you should assess the rubber compound quality, as high-quality materials can provide better resistance to cuts and punctures, thus extending the lifespan of the tracks. Overall, considering these factors will help in selecting the best rubber tracks to meet your heavy machinery needs effectively.

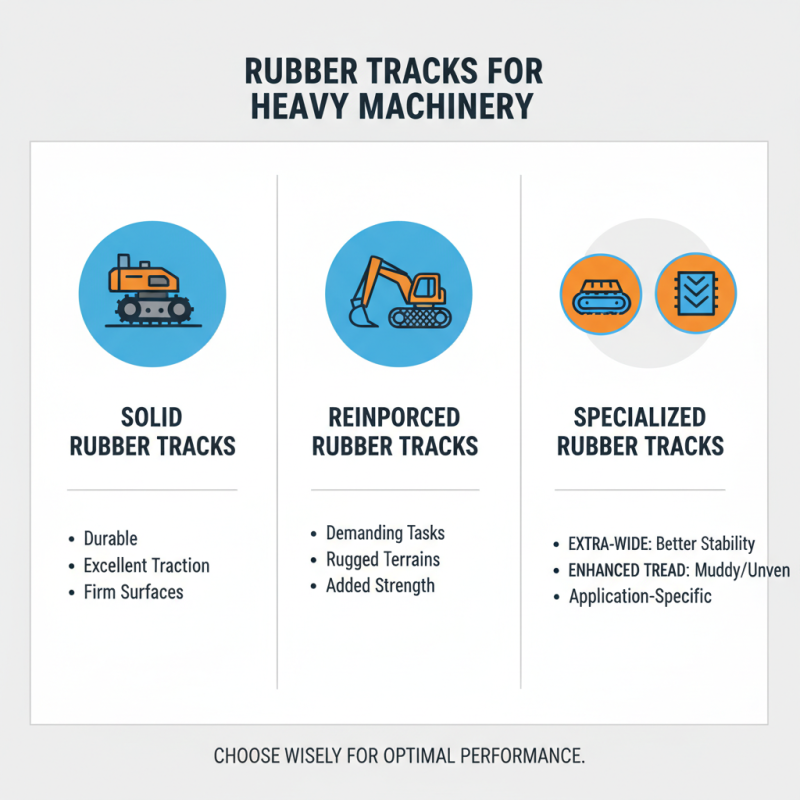

When selecting rubber tracks for heavy machinery, it’s essential to understand the different types available, as they each cater to specific equipment and operating conditions. Common categories include solid rubber tracks, which are durable and provide excellent traction on firm surfaces, and reinforced rubber tracks, designed to withstand the rigors of more demanding tasks and terrains. Additionally, there are specialized tracks with features like extra-wide designs for better stability and tracks with enhanced tread patterns for optimal grip in muddy or uneven landscapes.

Tips for selecting the right rubber tracks include assessing the type of terrain your equipment will predominantly operate on. For instance, if your machinery often works on delicate ground, opting for tracks with a softer rubber compound will minimize soil disturbance. Furthermore, consider the load capacity and size compatibility of the tracks with your heavy machinery to avoid operational mishaps. Always consult with experts or suppliers who can provide guidance tailored to your specific needs and the conditions you frequently encounter.

Finally, keep in mind the maintenance aspect of rubber tracks. Regularly inspecting tracks for wear and tear can prolong their lifespan. Additionally, investing in tracks designed for easy installation can save time and reduce labor costs, enhancing overall efficiency in your operations.

Rubber tracks have gained increasing popularity in heavy machinery applications due to their numerous advantages over traditional steel tracks. One of the most significant benefits is their ability to provide superior traction on soft or uneven surfaces, which is critical for machinery operating on construction sites or agricultural landscapes. According to industry reports, rubber tracks can enhance traction by up to 30% compared to steel tracks, significantly improving operational efficiency. Additionally, because rubber tracks are lighter, they reduce the overall weight carried by the machine, helping to minimize soil compaction and protect the underlying terrain.

When selecting rubber tracks, it’s essential to consider the specific needs of your machinery and work environment. One key tip is to assess the tread pattern of the rubber track; deeper treads are generally more effective in muddy conditions, while a more shallow tread offers better performance on compact surfaces. Another useful tip is to check the track's width and length, ensuring it matches your equipment's specifications for optimal performance. Regular maintenance, such as cleaning and inspecting for wear, can also extend the lifespan of your rubber tracks, often documented to last 2-3 times longer than steel tracks under similar conditions.

Furthermore, the noise level associated with rubber tracks is considerably lower, providing a more pleasant working environment. Studies suggest that rubber tracks can reduce noise by approximately 5-10 dB compared to steel, making them an excellent choice for urban construction projects where noise regulations are stringent. Ultimately, understanding these benefits can guide machinery operators toward making informed decisions that lead to enhanced productivity and cost-effectiveness.

When selecting the best rubber tracks for your heavy machinery, several key features should be considered to ensure high-quality performance and durability. First, the material composition of the rubber tracks is crucial. Look for tracks made from high-grade rubber that can withstand harsh conditions and provide excellent traction. The ability to resist abrasions, cuts, and tears will greatly enhance the lifespan of the tracks, making them a wise investment for your machinery needs.

Another important aspect to consider is the tread pattern. A well-designed tread pattern not only improves traction but also facilitates better handling and stability, especially on uneven terrain. Deep treads are typically more effective for off-road applications, while smoother treads may be suitable for paved surfaces. Additionally, check the track width and height, as these dimensions can impact the overall stability and load-bearing capacity of the machinery. Ensuring a perfect fit for your machine can prevent undue wear and improve efficiency during operation.

This chart displays key performance metrics for high-quality rubber tracks, helping you evaluate options based on weight capacity, durability, flexibility, price, and warranty offerings.

To extend the life of rubber tracks on heavy machinery, regular maintenance is essential. One key aspect is to keep the tracks clean and free of debris. After each use, operators should inspect the tracks for dirt, stones, or other materials that can cause wear. Cleaning the tracks with a high-pressure washer can prevent the buildup of grime that may lead to deterioration over time. Additionally, ensuring that the machinery operates on the correct terrain can significantly reduce unnecessary strain on the tracks, preserving their longevity.

Another important maintenance tip is to regularly check the tension of the rubber tracks. Proper tension ensures optimal performance and prevents premature wear. Operators should refer to the machinery's manual for specific tensioning guidelines and make adjustments as necessary. Furthermore, visual inspections for signs of cracks, tears, or uneven wear can help identify issues before they escalate. Addressing these problems early can not only extend the life of the rubber tracks but also enhance the overall efficiency of the machinery. Ensuring that the machinery is routinely serviced by qualified personnel can also contribute to the durability and efficiency of rubber tracks.

| Track Size (inches) | Material Quality | Durability Rating | Maintenance Tips | Expected Lifespan (hours) |

|---|---|---|---|---|

| 400 x 86 | High-quality rubber blend | 9/10 | Regular cleaning and inspection, proper alignment | 2000 |

| 450 x 100 | Premium rubber with armor | 10/10 | Monitor tread wear and avoid sharp edges | 2500 |

| 450 x 80 | Standard rubber compound | 7/10 | Regular inspections, keep tracks clean | 1800 |

| 500 x 80 | High-strength rubber | 8/10 | Check for cracks, avoid overloading | 2200 |

| 500 x 100 | Reinforced rubber | 9/10 | Store in a cool, dry place, check alignment | 3000 |