When it comes to choosing the right used rubber tracks for your machinery, expert opinions can guide you. Steve Johnson, a leading specialist in rubber tracks, emphasizes, "Selecting the proper tracks can significantly improve performance and longevity." Understanding your equipment's needs is crucial.

Used rubber tracks vary in quality and specifications. Assessing wear, tread pattern, and size is essential. Ignoring these factors can lead to costly mistakes. The right selection enhances traction and stability.

Many users overlook minor details, which can impact efficiency. Take time to evaluate options. Consider the terrain and intended use. This decision deserves careful thought, as it directly affects productivity and safety. Making a choice without due diligence could lead to regrets.

When selecting used rubber tracks for your equipment, several factors are essential. Start with the size. Ensure the tracks match your machine's specifications. Incorrect sizing can lead to performance issues. Measure the existing tracks if possible.

Next, assess the tread condition. Look for signs of wear or damage. Cracks, tears, and uneven wear can indicate a short lifespan. You don't want to invest in tracks that won't hold up. A thorough inspection can save you from costly replacements later.

Also, consider the environment where you'll be using the equipment. Different terrains require different tread designs. Muddy or wet conditions may need deeper treads. On harder surfaces, a flatter design may perform better. Think about how your choice will impact efficiency. Each decision plays a role in overall functionality and performance.

When selecting used rubber tracks, compatibility with your equipment is crucial. Begin by identifying your machine's model and specifications. Each model has unique requirements for size, width, and tread design. Missing these details can lead to costly mistakes.

Measure the dimensions of your current tracks. Often, it's easy to overlook subtle differences in size. A tape measure can be your best friend here. Check the width and the pitch. It can save you from the hassle of returns. Reviews and recommendations may help, but personal measurement is the best way.

Look closely at the tread pattern. Some patterns work better in certain terrains. This aspect can directly affect your equipment's performance. If the tread is not suited for your work environment, you may encounter issues. Compatibility is not simply about fitting; it’s about efficiency. Don't rush this decision. Take the time to assess thoroughly.

When evaluating used rubber tracks, the condition and quality are crucial factors. Begin by examining the tread depth. A track with at least 50% tread depth is ideal for optimal performance. According to industry reports, tracks worn more than 50% might compromise equipment efficiency. Look for cracks or damage. Small cracks may not be serious, but larger ones can lead to failure.

Next, check for signs of uneven wear. This could indicate misalignment in the equipment. Uneven wear affects tracking and can result in costly repairs. Data shows that nearly 30% of used tracks show significant uneven wear. This can severely impact functionality, leading to operational delays.

Additionally, inspect the internal structure of the tracks. A good track should have a solid foundation without visible tearing. Reports indicate that 20% of used tracks fail due to internal damage. It is essential to prioritize tracks with a strong core. These factors collectively contribute to the longevity of rubber tracks, influencing your equipment's performance and safety on the job.

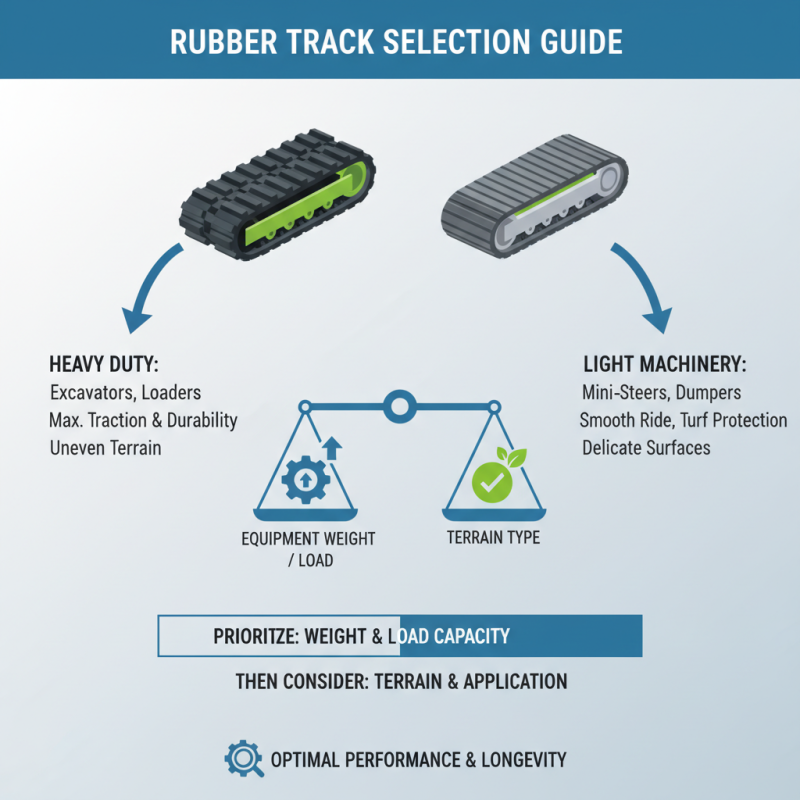

Choosing the right used rubber tracks can be daunting. The market offers various types tailored for specific needs. Identifying the correct type is crucial for optimal performance and longevity of your equipment. Some tracks are designed for heavy-duty use, while others cater to lighter machinery. Consider the weight and load capacity of your equipment before making a choice.

Different rubber tracks have unique tread patterns. The tread affects traction, stability, and wear resistance. Some tracks have a more aggressive design for rough terrains. Others are smoother, providing a quieter operation on hard surfaces. Be mindful of how well the tread matches your usual work conditions. This will ensure efficiency and safety during use.

Inspecting the condition of used rubber tracks is vital. Check for signs of wear, cracks, or tears. It’s common for tracks to show signs of aging even if they seem functional. Reflect on whether the price justifies the condition. Sometimes, a higher initial cost may lead to better performance and durability. Remember to weigh your options carefully and consider what works best for your situation.

When purchasing used rubber tracks, budget becomes crucial. Prices can vary significantly, so doing your research helps. Understand your equipment's specific requirements. Costs often depend on size and condition. Make sure to check multiple sellers. Comparing prices provides insights into reasonable deals.

In your budget, include installation costs. Sometimes, installation requires specialized tools or knowledge. You might also need to account for potential repairs. Overlooking these can lead to unexpected expenses. Aim to set aside a small buffer for emergencies. This extra fund can be a lifesaver.

Evaluate the overall condition before finalizing any purchase. Look for signs of wear, cracks, or damage. Inspect the tread pattern carefully. Sometimes, a lower price can lead to higher long-term costs if the tracks aren't reliable. Balancing initial costs with long-term value is essential.