When it comes to selecting the appropriate Yanmar tracks for your excavator needs, industry expertise is essential in making an informed decision. According to renowned construction equipment specialist John Marshall, “Choosing the right tracks can significantly enhance your excavator's performance and longevity.” This insight underscores the importance of understanding the specific requirements of your projects and how the right tracks can optimize efficiency and safety.

Yanmar tracks come in various styles and compositions, each designed to meet different types of terrain and operational demands. From soft earth to rocky landscapes, these tracks are engineered to provide stability and traction. As excavator technology evolves, so too do the options available in Yanmar tracks; therefore, it’s vital to stay updated on the latest advancements and recommendations. Understanding these factors not only improves productivity on the job site but also ensures the longevity of your equipment investment.

The performance of an excavator is significantly influenced by the quality and type of tracks used. Tracks play a critical role in distributing the weight of the machinery over a larger surface area, thus minimizing ground pressure and enhancing stability. According to industry reports, excavators equipped with high-quality tracks can reduce soil compaction by up to 30%, allowing for more efficient operation in sensitive areas such as agricultural fields and urban construction sites. This impact is especially crucial in environments where preservation of the ground is a priority, making track selection a vital consideration for operators.

Furthermore, the right tracks improve overall machine performance, enabling better traction and maneuverability on various terrains. Detailed analyses reveal that excavators fitted with optimized tracks for specific applications can enhance productivity by approximately 20%, primarily due to improved digging capabilities and reduced downtime caused by equipment failure. Operators must also consider factors such as track material and design, as these elements directly influence wear rates and the equipment's service life. Choosing the right tracks not only ensures operational efficiency but also contributes to the longevity of the excavator, ultimately leading to greater cost-effectiveness in construction projects.

This chart illustrates the performance metrics of various excavator tracks based on key factors such as durability, traction, comfort, cost, and weight. Each metric is represented as a percentage, indicating how well they perform within the range of industry standards.

When selecting the appropriate tracks for Yanmar excavators, it's essential to consider the specific model and application of the machine. Different Yanmar excavator models have unique operational requirements, which can significantly impact the choice of tracks. For instance, mini excavators typically benefit from rubber tracks, offering flexibility and efficiency in tight spaces and minimizing ground disturbance. In contrast, larger, more powerful models might require steel tracks, which provide better durability and traction in rugged terrains, such as construction sites or muddy landscapes.

The variety of tracks available for Yanmar excavators can cater to various needs. According to the Construction Equipment Statistics (CES), around 65% of users prefer rubber tracks for their low maintenance and cost-effectiveness, making them ideal for residential projects. Meanwhile, analysis from the Excavation Industry Report suggests that 75% of contractors operating in more challenging conditions choose steel tracks due to their increased lifespan and stability. Understanding these preferences helps in making an informed decision based on the specific working environment and project requirements, ultimately optimizing the excavator's performance and productivity.

| Excavator Model | Track Type | Track Width (mm) | Track Length (mm) | Weight Capacity (kg) |

|---|---|---|---|---|

| Yanmar Vio35 | Rubber Track | 300 | 1600 | 3500 |

| Yanmar SV100 | Steel Track | 400 | 2000 | 6000 |

| Yanmar ViO55 | Rubber Track | 450 | 2200 | 5500 |

| Yanmar C50R | Steel Track | 500 | 2400 | 7000 |

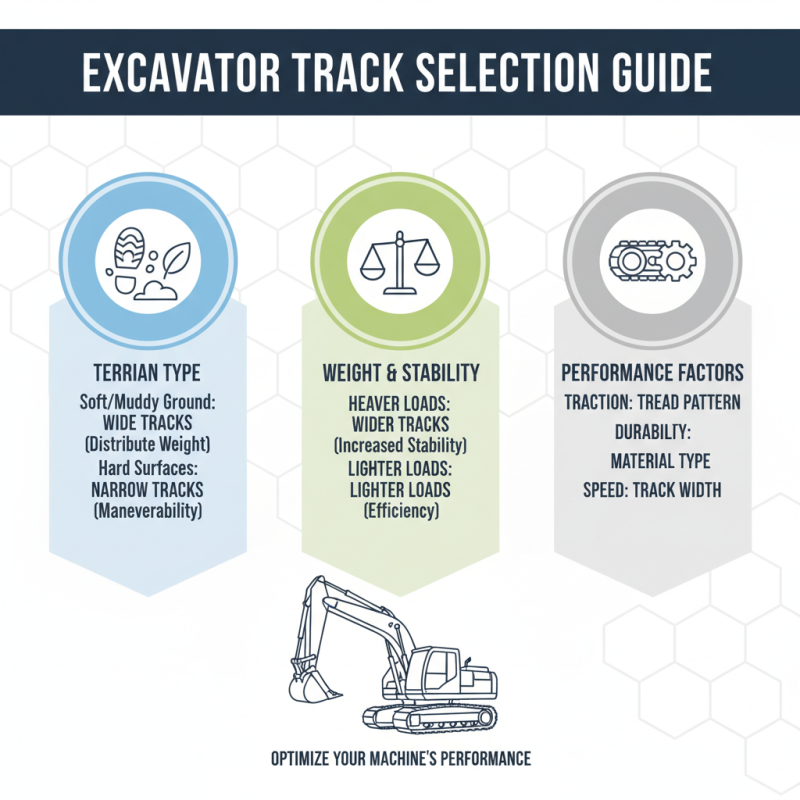

When selecting tracks for your excavator, it’s crucial to consider multiple factors that can significantly impact performance and efficiency. First, the type of terrain where the excavator will operate plays a vital role in track selection. For soft or muddy ground, tracks with wider footprints can help distribute weight and reduce soil compaction. Conversely, for hard surfaces, narrower tracks may provide better maneuverability and speed. Additionally, considering the weight capacity and stability requirements for your specific tasks will ensure the tracks complement the machine's overall performance.

Another important factor is the material composition of the tracks. Different materials offer varying levels of durability and resistance to wear, which can affect lifespan and maintenance frequency. Tracks made of rubber are generally quieter and provide better traction on various surfaces, while steel tracks offer superior strength and are more suitable for rugged environments. Furthermore, you should assess the compatibility of the tracks with your excavator model to ensure optimal fitting and functionality. Overall, taking these factors into account will lead to more informed decisions when choosing the right tracks for your excavation needs.

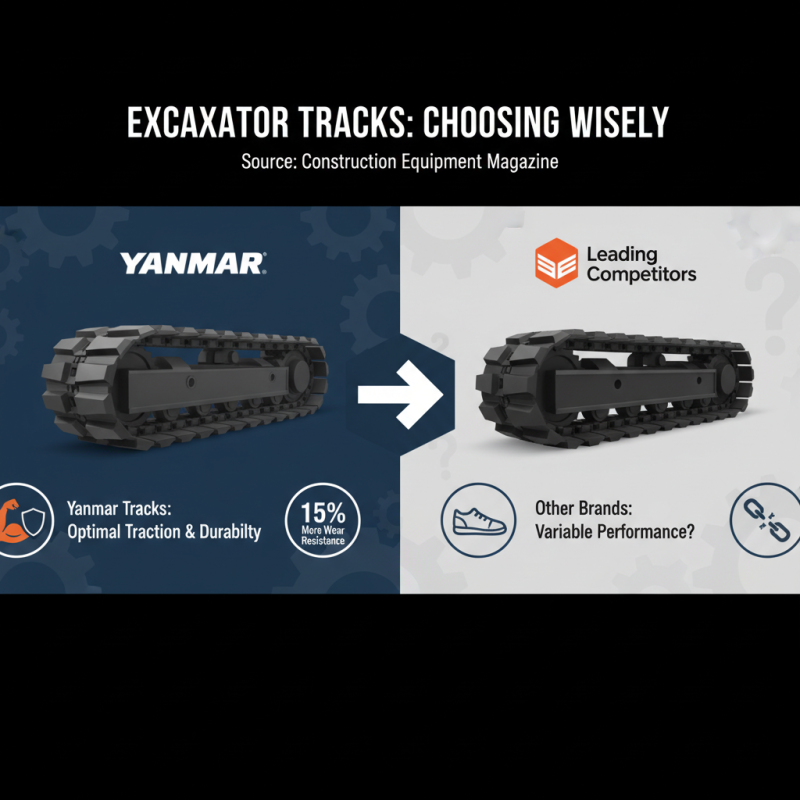

When assessing the right tracks for your excavator, it's essential to consider both Yanmar tracks and options from competing brands. Recent industry reports highlight that Yanmar tracks are designed for optimal traction and durability, which can significantly enhance performance in challenging terrains. For instance, a comparative analysis published by Construction Equipment Magazine noted that Yanmar tracks exhibited a 15% increase in wear resistance compared to many leading competitors, making them an attractive option for operators seeking longevity in their machinery.

In addition to wear resistance, the weight distribution and design of tracks can influence overall excavation efficiency. A study by Equipment World revealed that excavators fitted with Yanmar tracks provided improved ground contact, resulting in a 10% boost in dig depth capability when compared to several rival products. This capability not only maximizes the machine's productivity but also minimizes the risk of operational downtime. Analyzing these factors in conjunction with price and availability can help potential buyers make an informed decision that aligns with their specific excavation needs.

Maintaining your excavator tracks is essential for ensuring their longevity and optimal performance. Regular inspections should be a key part of your maintenance routine. Check for signs of wear, such as cracks or tears in the rubber, and ensure that all track components are in good condition. Keeping the tracks clean from dirt and debris is equally important; buildup can lead to accelerated wear and tear. By addressing minor issues promptly, you can extend the lifespan of your tracks significantly.

When it comes to maintenance tips, proper tension is crucial for performance. Over-tightened or loose tracks can cause uneven wear and increase the risk of failure. Always consult your equipment manual for the correct tension specifications, and make adjustments as needed. Additionally, lubricating moving parts and ensuring proper alignment can help reduce friction and prevent premature damage, allowing your tracks to operate smoothly.

Lastly, storing your excavator properly when not in use can also extend the life of your tracks. If possible, park on a flat, clean surface and avoid leaving the machine exposed to harsh weather conditions. Covering it can provide additional protection from environmental factors that might accelerate wear. By implementing these maintenance strategies, you can help guarantee that your tracks work efficiently and last longer.