In the rapidly evolving construction industry, the performance of excavators hinges significantly on the quality and suitability of their tracks. Among the plethora of options available, Takeuchi rubber tracks have emerged as a cornerstone for enhancing excavation efficiency and reducing operational hurdles. According to industry reports, excavators equipped with high-performance rubber tracks can improve traction by up to 30%, ensuring optimal functionality in various terrains. This statistic underscores the critical role that Takeuchi rubber tracks play in maximizing the performance of heavy machinery, granting operators increased stability and maneuverability.

Experts in the field, such as John Miller, a leading authority on construction equipment technology, emphasize this point: "The right rubber tracks not only enhance an excavator's performance but also contribute significantly to its longevity and maintenance costs." His insights highlight the necessity of selecting quality tracks that cater to specific job requirements, paving the way for improved productivity on-site. The adoption of Takeuchi rubber tracks is not merely a choice; it is a strategic decision that influences overall operational success, making them indispensable in the modern excavation landscape.

High-quality rubber tracks are crucial for optimal excavator performance, directly impacting efficiency, mobility, and operational costs. According to industry standards, the right tracks can enhance the performance of excavators by up to 20%. Durable rubber tracks provide better traction and stability, allowing machines to operate effectively on various terrains, from soft and muddy ground to rocky surfaces. This versatility is vital in ensuring that projects progress on schedule, minimizing downtime due to equipment failure or inefficiency.

In addition, the weight distribution capabilities of top-grade rubber tracks reduce ground pressure, effectively minimizing site disturbance and environmental impact. Studies show that using high-quality tracks can lower the ground pressure exerted by excavators by as much as 30%. This is particularly important in urban or sensitive landscapes, where soil compaction can adversely affect surrounding structures and vegetation. Furthermore, when compared to steel tracks, rubber tracks offer a notable reduction in wear and tear on the machine, translating to lower maintenance costs and longer operational lifespans. Thus, investing in high-quality rubber tracks represents an essential consideration for maximizing excavation efficiency and sustainability.

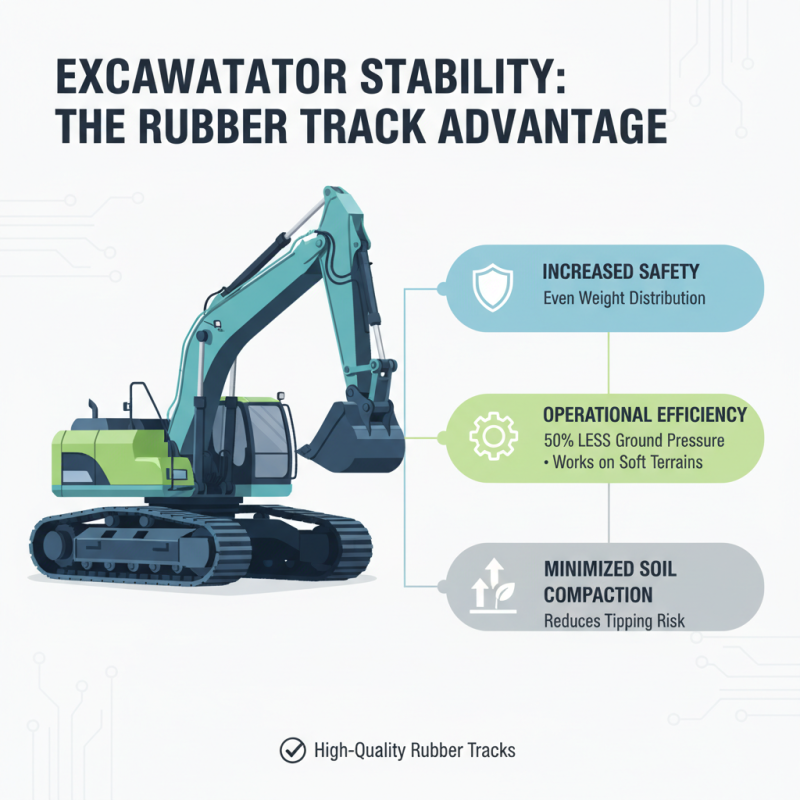

The stability of an excavator is crucial not only for operator safety but also for maximizing operational efficiency. Rubber tracks play a pivotal role in achieving this stability, as they distribute the weight of the machine more evenly across the ground. According to industry studies, excavators equipped with high-quality rubber tracks can reduce ground pressure by up to 50% compared to those with traditional steel tracks. This significant reduction in ground pressure minimizes soil compaction, allowing the excavator to work on softer terrains without the risk of sinking or tipping.

Additionally, rubber tracks improve traction and maneuverability, essential attributes for executing precise movements in variable job site conditions. Research has shown that machines utilizing rubber tracks can achieve up to 30% better traction on uneven surfaces than their steel-tracked counterparts. This enhanced grip enables operators to work efficiently on slopes and unstable ground, where conventional tracks may struggle, thus reducing the likelihood of accidents and improving productivity levels. By leveraging the benefits of rubber tracks, contractors can ensure greater stability and a smoother operation, paving the way for improved project outcomes.

Rubber tracks offer several advantages over traditional steel tracks when it comes to optimal excavator performance. One of the most significant benefits is the enhanced traction and stability they provide on various terrains. Rubber tracks are designed to distribute the weight of the excavator evenly, reducing ground pressure and minimizing the risk of soil compaction. This feature allows for better maneuverability and less damage to the worksite, making rubber tracks particularly suitable for sensitive environments such as landscaping or agricultural applications.

Another key advantage of rubber tracks is their superior ride comfort. Unlike steel tracks, rubber tracks absorb shocks and vibrations, resulting in a smoother operation for both the operator and the machine itself. This comfort translates into increased productivity, as operators can work longer hours without experiencing fatigue. Additionally, rubber tracks tend to be quieter than steel tracks, which contributes to a more pleasant working environment, especially in residential areas. Ultimately, these advantages highlight rubber tracks as a smart choice for maximizing efficiency and effectiveness when operating excavators.

Maintaining rubber tracks is crucial for enhancing the overall performance of excavators, particularly those utilizing tracks designed for off-road and rough terrain. Regular maintenance practices can significantly extend the longevity of tracks, allowing for optimal functionality and reducing the risks of costly downtime. A study by the Construction Industry Institute indicates that up to 25% of maintenance costs in heavy machinery can be attributed to track issues, highlighting the importance of proactive management.

Regular inspections are essential in identifying wear and tear before they lead to significant failures. Operators should check for signs of uneven wear, cracks, and foreign debris lodged in the track system. A report from the Association of Equipment Manufacturers suggests that operators who carry out monthly inspections can increase their equipment's life span by up to 40%. Additionally, maintaining proper tension is vital as over-tightened tracks can cause excessive wear on both the tracks and the drive system, while loose tracks may derail, leading to operational delays.

Proper cleaning of rubber tracks after usage is also a fundamental aspect of maintenance. Accumulation of dirt and debris can lead to premature deterioration, affecting both performance and safety. According to industry experts, a clean track can reduce resistance and improve fuel efficiency by as much as 15%, emphasizing the link between maintenance practices and operational efficiency. Therefore, adopting a meticulous maintenance routine is essential for maximizing the life and performance of rubber tracks in excavators.

| Maintenance Practice | Frequency | Impact on Track Longevity | Notes |

|---|---|---|---|

| Inspecting for Damage | Weekly | High | Early detection can prevent further damage. |

| Cleaning Tracks | After Every Use | High | Prevents debris buildup that can cause wear. |

| Proper Tension Adjustment | Monthly | Critical | Incorrect tension can lead to premature failure. |

| Lubrication of Moving Parts | Every 50 Operating Hours | Medium | Reduces friction and wear. |

| Monitoring Soil Conditions | During Every Job | High | Soft or wet soil can strain tracks. |

The width of rubber tracks plays a crucial role in determining soil compaction and excavation efficiency. Wider tracks distribute the weight of the excavator over a larger surface area, which helps to minimize ground pressure. This is particularly important in soft or sensitive soil conditions, where excessive pressure can lead to deformation and compaction. By reducing soil compaction, wider tracks allow the excavator to operate more effectively without adversely affecting the surrounding terrain, making it ideal for delicate excavation projects.

In addition to minimizing soil impact, the width of the tracks can influence the overall stability and traction of the excavator. Wider tracks provide better grip, enhancing machine performance on uneven or slippery surfaces. This increased stability allows operators to perform tasks with greater precision and reduces the risk of accidents or machine tipping. Consequently, choosing the right track width is essential not only for optimizing excavation efficiency but also for ensuring the safety and longevity of the equipment in diverse working environments.