When it comes to maximizing the performance of heavy machinery, particularly in construction and landscaping, the selection of the right tracks is crucial. The Kubota SVL75, a highly regarded compact track loader, has gained popularity for its remarkable versatility and power. According to a recent industry report by Equipment Today, the market for compact track loaders is expected to grow significantly, driven by increasing demand in urban infrastructure projects. Choosing the right Kubota SVL75 tracks is essential not only for enhancing the machine’s operational efficiency but also for ensuring longevity and reducing maintenance costs.

In the words of industry expert Sarah Thompson, an experienced construction equipment analyst, "The choice of tracks can make a significant difference in achieving optimal productivity with the Kubota SVL75." This emphasizes the importance of understanding the various track types available, including rubber and steel options, as each serves unique operational needs depending on the terrain and workload. With the right information and expert insights, operators can optimize their Kubota SVL75 tracks selection to achieve superior performance that meets the demands of today's dynamic worksite environments.

When it comes to maximizing the performance of heavy machinery like the SVL75, the significance of track selection cannot be overstated. Tracks are more than just components that allow movement; they are integral to the machine's overall functionality and efficiency. Choosing the right tracks means considering various factors, such as terrain type, load capacity, and operational demands. Improper track selection can lead to inefficiencies, increased wear and tear, and even safety hazards. Therefore, understanding the specific requirements of your work environment will go a long way in ensuring that you select tracks that can withstand the challenges posed by different surfaces.

Another crucial aspect of track selection is the impact it has on performance metrics such as traction, maneuverability, and stability. Different track designs can provide varying levels of grip, making it essential to select tracks that match the intricacies of your operating environment. For instance, if working in muddy or loose soil conditions, opting for tracks with a broader surface area can improve stability and reduce the risk of getting stuck. Additionally, selecting the appropriate track material can enhance durability and resistance to wear, ultimately translating to lower maintenance costs and longer service life. In essence, understanding the importance of track selection equips operators with the knowledge needed to make informed decisions, ensuring optimal performance and long-term functionality of their equipment.

When selecting tracks for the Kubota SVL75, several key factors can significantly impact performance and longevity. First, it's essential to consider the type of material used in the tracks. High-quality rubber tracks are widely regarded for their resilience and ability to withstand harsh working conditions. According to a study by the Equipment Manufacturers Association, tracks made from a blend of synthetic rubber and steel cords can increase wear resistance by up to 30%. This durability is critical in applications where the machine is frequently traversing rough terrain or operating in wet conditions.

Another important factor is the track width and design. Wider tracks provide better weight distribution, reducing ground pressure, which is beneficial for traversing soft or muddy surfaces. Research published in the Journal of Construction Equipment Management indicates that wider tracks can improve traction by nearly 25% in soft soil conditions. Furthermore, the tread pattern should be selected based on the specific work environment; patterns designed for mud traction will differ considerably from those optimized for hard surfaces. Ensuring that the chosen tracks match the operational needs of the Kubota SVL75 is vital for maximizing efficiency and reducing the risk of track failure under load.

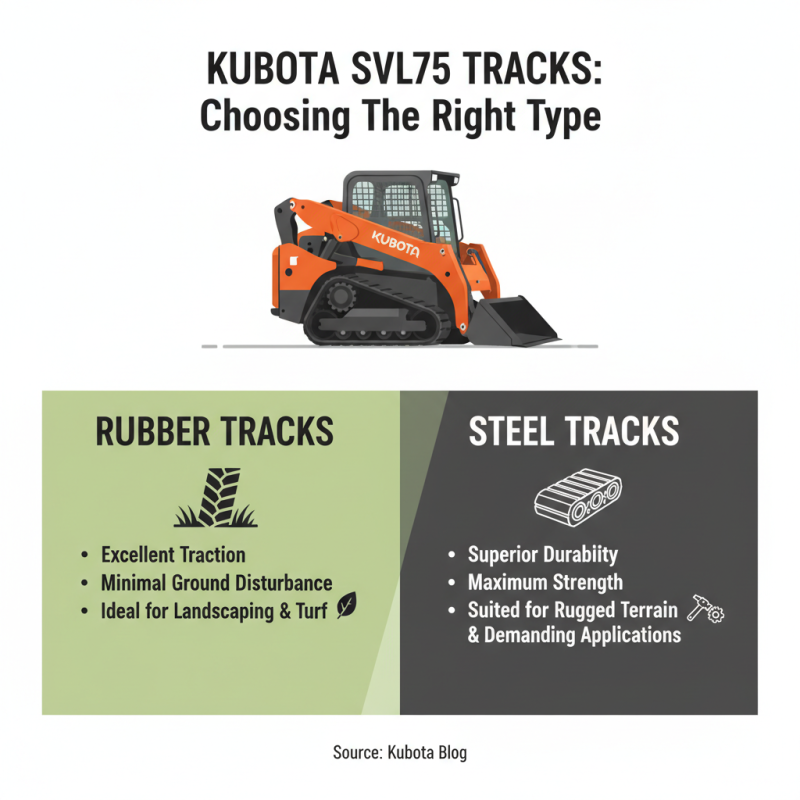

When selecting tracks for the Kubota SVL75, it's essential to consider the different types available and their unique benefits. Generally, tracks can be categorized into rubber tracks and steel tracks. Rubber tracks are widely favored for their ability to provide excellent traction while minimizing ground disturbance. This type is ideal for landscapers and operators who require a balance between performance and preserving the working surface. On the other hand, steel tracks are known for their durability and strength, making them suitable for more rugged terrain and demanding applications.

When choosing the right tracks for optimal performance, here are a couple of tips to keep in mind. First, assess the working environment where your Kubota SVL75 will be primarily used. If you frequently operate on softer or sensitive grounds, rubber tracks are likely a better choice, as they offer greater flotation and reduce the risk of damage to the landscape. Alternatively, if your work involves heavy loads on rough terrain, investing in steel tracks could enhance your machine’s stability and longevity.

Another important consideration is the tread pattern of the tracks. Different tread designs provide varying levels of traction and efficiency depending on the surface conditions. Some tracks are designed with aggressive treads for muddy or slippery environments, while others feature smoother patterns for paved or compacted surfaces. By selecting tracks that align with your specific operational needs, you can ensure that your Kubota SVL75 performs at its best in any condition.

Proper maintenance of tracks is essential for maximizing the performance and lifespan of heavy machinery like the Kubota SVL75. Research from industry reports indicates that regular inspections can extend the life of tracks by up to 30%. Operators should routinely check for signs of wear and tear, such as cracking or missing segments, to prevent unexpected downtimes and costly repairs. Additionally, maintaining optimal tension is crucial; tracks that are either too loose or too tight can lead to accelerated wear, reducing their overall effectiveness and lifespan.

Lubrication plays a vital role in track maintenance as well. Studies suggest that keeping those components well-lubricated can significantly diminish the friction and heat that lead to premature deterioration. It’s recommended to use high-quality lubricants that are specifically designed for heavy-duty applications, ensuring that the track's operational smoothness is preserved. Furthermore, regularly cleaning the tracks from mud, debris, and other contaminants can help in maintaining their integrity and performance. By adopting these maintenance practices, operators can ensure that their equipment functions efficiently, thereby maximizing productivity and reducing operational costs.

| Tip Category | Tip Description | Frequency | Expected Outcome |

|---|---|---|---|

| Track Selection | Choose tracks based on the operating environment (soft soil, rocky terrain). | Before purchase | Improved traction and reduced wear. |

| Regular Inspection | Inspect tracks for damages and wear regularly. | Weekly | Prevention of further damage. |

| Cleaning | Clean tracks after operation to remove debris and mud. | After every use | Enhanced lifespan and performance. |

| Proper Tensioning | Ensure tracks are properly tensioned to prevent slippage. | Monthly | Maximized traction and minimized wear. |

| Lubrication | Apply lubrication to moving parts to reduce friction. | Every 50 hours of operation | Reduced wear and tear. |

| Storage | Store tracks in a dry place away from direct sun. | During off-season | Longevity of tracks. |

When it comes to maintaining the performance of heavy machinery like the Kubota SVL75, the condition of your tracks plays a crucial role. Recognizing the signs that it’s time to replace your tracks can significantly enhance not only the machine’s efficiency but also its lifespan. Industry data indicates that tracks typically need replacement after 1,000 to 1,500 hours of operation, but this can vary based on usage and environmental conditions. Factors such as exposure to sharp rocks, mud, or excessive heat can lead to accelerated wear and tear, making it essential to regularly inspect for visible signs of damage.

Key indicators that replacement is necessary include cracks or tears on the track surface, uneven wear patterns, and reduced grip on various terrains. A recent report highlighted that worn tracks can decrease machine efficiency by up to 20%, impacting productivity levels on job sites. Additionally, performance metrics indicate that operating machinery with compromised tracks can lead to increased fuel consumption, further inflating operational costs. Being vigilant and proactive in monitoring track condition not only ensures optimal performance of your Kubota SVL75 but also aids in avoiding the costly repercussions of negligence.