In 2026, construction and excavation industries face rising demands. Efficiency, durability, and performance are paramount. Yanmar excavator tracks play a crucial role in meeting these needs.

With advanced design, Yanmar tracks ensure stability on uneven terrain. They provide better traction, reducing risks of slips or accidents. Reliability becomes vital in projects that operate under tight deadlines. Yet, some operators may overlook the importance of regular maintenance. Neglecting track care can lead to costly downtime and repairs.

Choosing the right tracks can seem simple. However, not all tracks perform alike. Investing in Yanmar excavator tracks is a strategic choice. They enhance productivity and safety. However, making this choice requires careful consideration of your machinery’s specific needs. Evaluating these factors ensures optimal performance in every job site.

High-quality tracks are vital for any excavator's performance. For heavy machinery, tracks do more than just provide mobility. They influence stability and traction. According to industry data, over 40% of machinery downtime can be attributed to track-related issues. This impacts productivity significantly.

Using durable tracks can mitigate these issues. Data shows that high-quality tracks can extend lifespan by up to 30%. This reduction in replacement frequency shows economic benefits. However, not all tracks are created equal. Some options may seem cost-effective initially but lead to higher costs long-term due to increased wear and maintenance.

Quality tracks enhance overall machine efficiency. They ensure optimal weight distribution and better ground contact. Conversely, subpar tracks can lead to uneven wear patterns. This not only affects functionality but may also cause unexpected breakdowns. Investing in quality tracks should be seen not just as a purchase, but as an integral part of effective equipment management.

When it comes to heavy machinery, tracks play a vital role in performance. For excavators, the right tracks can drastically improve efficiency. Durable construction ensures better traction in muddy or uneven terrains. This is crucial for various projects. Optimal grip contributes to smooth operations. It minimizes downtime caused by track failures.

Many operators overlook the significance of maintaining tracks. Neglected tracks can lead to reduced mobility and increased wear. In 2026, the landscape of heavy machinery demands premium performance. Regular inspections and timely replacements are essential. They save costs in the long run by avoiding unexpected repairs.

Ultimately, investing in high-quality tracks enhances load capacity and stability. Proper tracks allow for precise maneuvering, making tasks easier. However, one should remain aware of the needs of individual machinery. Each project may require different specifications. The right choice isn’t always clear, and this complexity invites frequent discussions.

In 2026, Yanmar excavator tracks will be crucial for heavy machinery operations. Recent industry reports indicate that track technology has advanced significantly. Innovations have focused on durability and performance. Stronger materials come into play. These increase the lifespan of tracks. According to industry data, new composite materials can improve resistance by up to 30%.

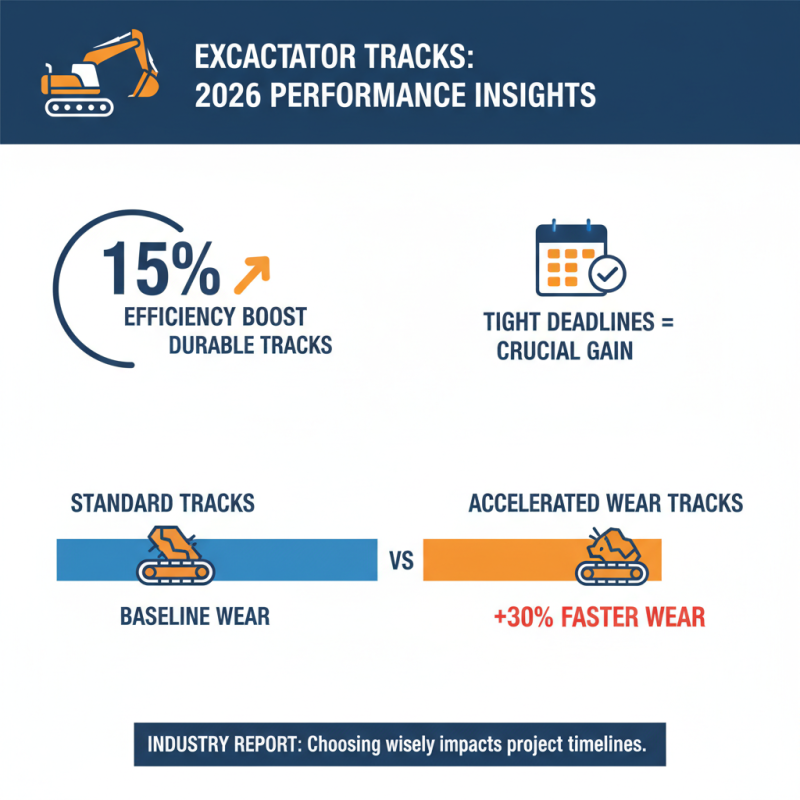

The growing demand for efficient machinery heightens the need for enhanced track designs. Advanced tread patterns provide better traction on uneven surfaces. They can reduce slippage, which is vital for productivity. Recent studies show that well-designed tracks can boost operational efficiency by 15%. However, not all operators understand the importance of regular maintenance. Neglecting track care can lead to rapid wear and increased costs.

Innovation is a double-edged sword. With advancements, there’s a learning curve. Many operators find it challenging to keep up with new technologies. Reports suggest a gap in training and knowledge among users. Without proper understanding, the benefits of new tracks may not be fully realized. Using modern tracks without adequate knowledge could lead to underperformance. Operators need to adapt and embrace ongoing learning to maximize potential.

Maintaining Yanmar excavator tracks is vital for heavy machinery's performance in 2026. Research shows that proper track maintenance can extend lifespan by up to 30%. Regular inspections can prevent costly repairs and downtime. Operators should check for wear and alignment issues frequently.

Tips: Always clean the tracks after each job. Remove debris and mud. This simple step improves lifespan. It can also enhance traction on different terrains.

Lubrication is key. Ensure that all moving parts are properly greased. This reduces friction and wear. A study indicates that proper lubrication can decrease failure rates by 15%. Ignoring lubrication can lead to premature wear. Operators often overlook this aspect, risking machinery health.

Lastly, consider environmental factors. Extreme temperatures can affect track performance. Operators should adjust maintenance routines based on weather conditions. Keeping track of these elements leads to better efficiency. Regular maintenance could save money in the long run. The effort put into care reflects on the equipment's reliability and longevity.

In 2026, the choice of excavator tracks can significantly impact performance. A recent industry report highlighted that durable tracks can enhance machinery efficiency by 15%. This increase is crucial when projects have tight deadlines. Comparisons between leading manufacturers reveal varied wear rates. Some tracks show a 30% faster wear under similar conditions.

Consider the different materials used for construction. Steel tracks often offer superior longevity but can add weight. Meanwhile, rubber tracks tend to be quieter and less damaging to sensitive surfaces. It's essential to weigh these factors based on specific project needs. One study found that rubber tracks can reduce soil compaction by up to 20%.

Reliability is another area of concern. Some brands report failure rates of over 10% in extreme conditions. This statistic raises questions about dependability. Choosing a track that balances durability and cost can be tricky. The market offers many options, but not all live up to their promises. Understanding these nuances is vital for making an informed decision in 2026.